FINISHING LEATHER

The final step in creating beautiful leather

Leather only becomes the material we appreciate so much in shoes during the final step. The process carried out in the finishing shop is responsible for this change, as it receives its elegant appearance and typical smell.

What does leather finishing mean?

Leather that comes from the tannery is rigid, still moist and not visually attractive. The last step, before it can be used to manufacture shoes, involves the leather being taken to the finishing shop. This step includes drying the leather, softening it and enhanced coloration of its refining details.

The leather cannot be processed after pure tanning: it is not ready for use until it has been finished. Leather finishing refers to all the steps that make up the process, such as milling, hemming, neutralising, dyeing, greasing, drying and embossing.

What does milling mean?

The first step of the process involves the leather’s water content being reduced. This stage is known as milling. This used to be done by hand but, today, milling machines, which squeeze the water from the leather, are used to make the process more simple.

What does samming mean?

The semi-dried hides are planed down (‘equalised’) to a predetermined layer thickness.

What is neutralisation?

Animal hides are still acidic until they are neutralised. The next step involves the hide being neutralised, i.e. deacidified. During this step, free acids and neutral salts are removed from the leather and into a barrel through means of brewing. This stage is very important in terms of making the hide suitable to wear.

How is leather dyed?

The leather being dyed is the step that follows the neutralisation stage. The hide is placed is huge barrels and repeatedly turned in organic or non-organic colour until the colour has penetrated all the fibres.

Integral colouration (also known as transparent colouration) is not to be mistaken with topping. This process solely results in a one-sided, surface-dyed leather. The colour is applied by means of a spray gun or by brushing the surface of the leather with the colour. Many low-priced leather shoes produced by other manufacturers are only top-dyed. Sioux uses exclusively dyed-through leather. This results in the colour being of a better quality, lasting longer and being abrasion-resistant. Small damage is immediately visible on top-dyed leather, as the undyed leather becomes visible if the material is scratched. Another important aspect is that dyed-through leather (used by Sioux) is much more breathable than top-dyed leather since the pores of the leather open during the dying process, whereas the pores close during the top-dyeing process.

Why is leather greased (oiled)?

Processed leather is relatively firm until this stage. The next finishing step is the so-called greasing process. This process is carried out in a hot air drum. Various mineral oils (or fats) are added and rotated. This makes the leather more supple, stretchy, tear-resistant and flexible, and adds the typical leather smell. This typical leather smell is therefore not the natural smell of animal skin, but a result of the processing.

What does chemical finish mean?

Another finishing step, which is carried out before the drying stage, is producing a glaze for the shaft leather. This involves the upper layer of the leather being refined. This glaze protects the leather from external influences and preserves the shiny surface.

Why is leather pressed?

The finished outer leather is stretched between metal plates or under heat radiators and dried at between 40 and 60 degrees Celsius. After the leather has been stored for one or two days, it is pressed at 90 degrees using heavy hand irons or a press, resulting in a wrinkle-free surface being formed. Following this stage and a lot of manual work, raw hides have now been turned into a premium material that can be used to create high-quality shoes.

Leather production

Leather has been manufactured since the early history of humankind, as this high-quality and durable raw material can be used to make shoes. Native Americans developed the first-known type of shoe – the moccasin. Tanned buffalo skin was used to make these shoes. The buffalo was hunted primarily as a source of meat, but the hides, tendons and bones were processed and used for many different purposes.

Types of leather

At Sioux we place value on offering premium quality and comfort as well as a modern look. As a result of the various types of leather, tanning processes and colours, Sioux incorporates over 200 different varieties of leather into its collections to ensure that the highest standards are met. From non-slip, smooth leather and colourful suede and nubuck leathers, to reptile, metallic and glossy looks, everything has the same inimitable Sioux quality.

Shoe leather

Choosing the leather is very easy when it comes to Sioux shoes: we only settle for the best.

Shoe construction techniques

Why are there so many different shoe models? The construction technique used by Sioux depends on what the shoe will be worn for and what the wearer requires from it. Because, ultimately, the shoe must have a perfect fit.

Things you should consider when buying shoes

The following 10 tips will give you a practical guide and help you with your next shoe purchase. Besides the right shoe size and width, an optimal fit, skilful workmanship and the use of high-quality materials for the upper, lining and outsole are also important factors when it comes to quality and selection. We want you to stay feeling comfortable in your shoes for as long as possible.

Crepe sole

Learn more about what is undoubtedly the most natural form of comfort - everything about this Sioux speciality can be found here.

Labelling of materials

A question frequently asked by our customers is: “How can I be sure that the material used is really genuine leather?"

The history of footwear

More than 40,000 years ago, people developed a need to protect their feet against adverse external conditions. It took several centuries, however, until the fashionable and comfortable footwear that we are familiar with today became available.

Sioux hallgus protect

The combination of high-quality leather and our innovative Sioux-Tex climate membrane will give your feet that “feel-good” feeling: whilst moisture and vapour are quickly wicked away from the shoes, water from the outside has no chance of getting in, meaning your feet are always warm and dry.

Sioux natural move system

The combination of high-quality leather and our innovative Sioux-Tex climate membrane will give your feet that “feel-good” feeling: whilst moisture and vapour are quickly wicked away from the shoes, water from the outside has no chance of getting in, meaning your feet are always warm and dry.

SiouxTex

The combination of high-quality leather and our innovative Sioux-Tex climate membrane will give your feet that “feel-good” feeling: whilst moisture and vapour are quickly wicked away from the shoes, water from the outside has no chance of getting in, meaning your feet are always warm and dry.

Shoe lining

Consumers often only pay attention to whether they like a shoe and whether it fits well. What is inside the shoe should also be a decisive factor: the shoe lining is often underestimated when buying shoes, despite being a key factor when it comes to comfort and health. Below we will explain the various types of shoe lining, their uses and the importance of shoe lining when it comes to your well-being.

Shoe soles

Whether they are a lightweight and flexible, feature unique air-cushioning or have a timeless and elegant leather sole: it's the perfect join of the shoe upper and sole which is the finishing touch to each and every shoe.

Shoe size and fit

As the foot performs a rolling motion when walking, it bears your weight in various areas and thus changes shape in doing so. The hallmark of a perfect-fitting shoe is that the toes and the foot itself have enough space within the shoe throughout this rolling motion and that the heel experiences sufficient grip. When a shoe fits, the heel does not slip out of the back of the shoe, and the shoe sits so perfectly in the midfoot area that the foot is supported – and is unable to slip forwards – hence the shoe pinching.

Shoe leather

Choosing the leather is very easy when it comes to Sioux shoes: we only settle for the best.

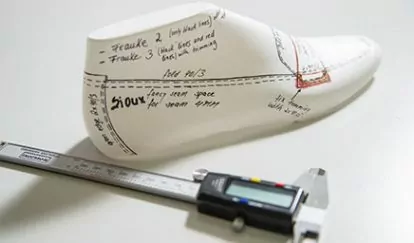

Shoemaking

There are lots of steps involved in making a shoe. From developing the model in the first instance, to the stamping, sewing and putting the finishing touches to the shoe at the very end.

Grashopper

In the 1960s, the natural form moccasin was a revolution. Today, the cult shoe is more topical than ever as a pioneer in modern casual wear.

DE

DE EN

EN FR

FR NL

NL